Corrosion-resistant Plastic Pneumatic Actuator Introduction

Corrosion-resistant plastic pneumatic actuators are designed to withstand aggressive environments. They are commonly used in industrial applications where resistance to chemical corrosion is crucial. Let’s delve into the key features of these actuators:

Material Composition:

These actuators are crafted from high-quality plastics, including:

FRPP (Flame-Retardant Polypropylene): Known for its excellent chemical resistance, FRPP can withstand a wide range of corrosive substances.

UPVC (Unplasticized Polyvinyl Chloride): UPVC offers good chemical stability and is suitable for various corrosive media.

CPVC (Chlorinated Polyvinyl Chloride): CPVC combines the benefits of PVC with enhanced chemical resistance, making it ideal for aggressive environments.

PPH (Polypropylene Homopolymer): PPH is resistant to acids, bases, and solvents, making it a reliable choice for corrosive applications.

PVDF (Polyvinylidene Fluoride): PVDF boasts exceptional chemical resistance, even at elevated temperatures.

Lightweight and Easy Installation:

These plastic actuators are significantly lighter than their aluminum alloy or stainless steel counterparts.

Their ease of installation ensures efficient setup and reduces labor time.

Standardized Connection Sizes:

The actuators adhere to industry standards such as ISO 5211 and NAMUR.

This compatibility simplifies integration with other components in the system.

In summary, corrosion-resistant plastic pneumatic actuators offer a reliable solution for harsh environments, combining durability, ease of installation, and standardized connections.

|

Product |

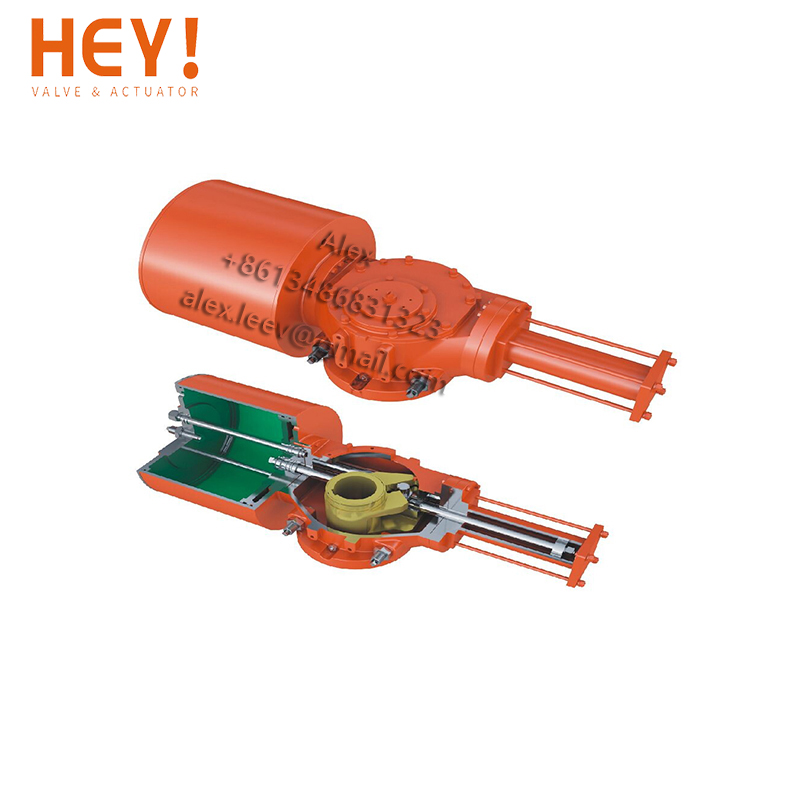

Corrosion-resistant Plastic Rack and Pinion Pneumatic Actuator |

|

Structure |

Rack and Pinion Rotary Actuator |

|

Rotary Angle |

0-90 Degree |

|

Air Supply Pressure |

2.5-8 Bar |

|

Actuator Body Material |

Corrosion-resistant Plastic |

|

Operating Temperature |

Standard Temperature:-20℃ ~ 80℃ Low Temperature:-15℃ ~ 150℃ High Temperature:-35℃ ~ 80℃ |

|

Connection Standard |

Air interface: NAMUR Mounting Hole: ISO5211 & DIN3337(F03-F25) |

|

Application |

Ball Valve, Butterfly Valve & Rotary Machines |

|

Cover Color |

Black,Brown & other Plastic Material Color |

Corrosion-resistant Plastic Rack and Pinion Pneumatic Actuator

Double Acting Torque(N.m.)

|

Model |

Air Pressure (Bar) |

|||||

|

3 |

4 |

5 |

5.5 |

6 |

7 |

|

|

PLT05DA |

13.3 |

18.3 |

23.4 |

26 |

28.5 |

33.6 |

|

PLT07DA |

32.9 |

45.6 |

58.3 |

65 |

71 |

83.7 |

|

PLT09DA |

77.7 |

107 |

436.3 |

150.9 |

165.4 |

194.8 |

Corrosion-resistant Plastic Rack and Pinion Pneumatic Actuator

Spring Return Torque(N.m.)

|

Air Pressure (BAR) |

4 |

5 |

6 |

7 |

Spring Torque |

||||||

|

Model |

Spring Qty |

start |

end |

start |

end |

start |

end |

start |

end |

start |

End |

|

PLTO5SR |

10 |

7.6 |

2.5 |

12.7 |

7.6 |

17.8 |

12.7 |

22.9 |

17.8 |

15.8 |

10.7 |

|

8 |

9.6 |

5.7 |

14.7 |

10.8 |

19.8 |

15.9 |

24.9 |

21 |

12.6 |

8.7 |

|

|

PLTO7SR |

10 |

19.9 |

7.6 |

32.6 |

20.3 |

45.3 |

33 |

58 |

45.7 |

38 |

25.7 |

|

8 |

25.1 |

15.2 |

37.8 |

27.9 |

50.5 |

40.6 |

63.2 |

53.3 |

30.4 |

20.5 |

|

|

PLTO9SR |

10 |

52.2 |

19.8 |

81.5 |

49.1 |

110.7 |

78.3 |

140 |

107.6 |

87.2 |

54.8 |

|

8 |

63.1 |

37.2 |

92.4 |

66.5 |

121.6 |

95.7 |

150.9 |

125 |

69.8 |

43.9 |

|

Dimensions Table(mm)

|

Model |

Z |

A |

E |

M |

N |

I |

J |

|

PLTO5 |

161 |

85 |

102 |

14 |

16 |

50 |

/ |

|

PLTO7 |

230 |

104 |

124 |

17 |

19 |

50 |

70.0 |

|

PLT09 |

313 |

122 |

147 |

22 |

20 |

70 |

/ |

Pneumatic Actuator FAQ:

Q1: Pneumatic Valve can’t Move ?

A1: Check the Solenoid Valve is normal or not;

Test the actuator separately with air supply;

Check the handle position.

Q2: Pneumatic Actuator with slow motion ?

A2: Check air supply is enough or not;

Test the Actuator Torque is ok or not for the valve;

Check Valve coil or other components are too tight or not;

Q3: Reply Devices without Signal ?

A3: Inspect and repair power circuit;

Adjust the cam to correct position;

Replace micro switches.