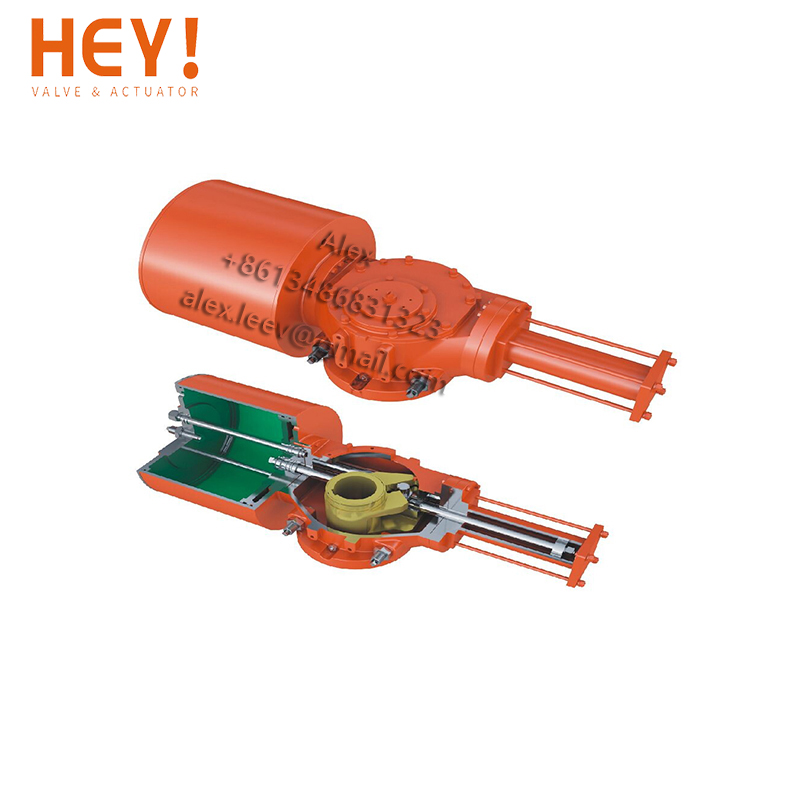

Heavy Duty Scotch Yoke Pneumatic Actuator introduction

Scotch Yoke type pneumatic actuators usually refer to “single-cylinder double-piston-variable-torque fork type” pneumatic actuators, which are a range of piston-type actuators and are suitable for valves with a 90 ° angle (such as ball valves, butterfly valves, Stop valve or metering control).

Heavy Duty Scotch Yoke Pneumatic Actuator Features

CE certificate and According with international Standards, such as NAMUR,ISO5211 and DIN.

Integrated Design with Stable Quality.

Dual Piston rack and Pinion Design with High Output Power.

Multi-position Indicator, On-site Visual Instruction.

Large operating force, Small flow resistance.

Novel Valve Body Design.

Large rated flow coefficient, large allowable pressure difference and excellent sealing performance.

| Product | Heavy Duty Scotch Yoke Pneumatic Actuator |

| Structure | Heavy Duty Scotch Yoke Pneumatic Actuator |

| Rotary Angle | 0-90 Degree |

| Air Supply Pressure | 2.5-8 Bar |

| Actuator Body Material | Aluminum Alloy, Stainless Steel, Carbon Steel. |

| Surface Treatment | Hard Anode Oxidation |

| Operating Temperature | Standard Temperature:-20℃ ~ 80℃

Low Temperature:-15℃ ~ 150℃ High Temperature:-35℃ ~ 80℃ |

| Connection Standard | Air interface: NAMUR

Mounting Hole: ISO5211 & DIN3337(F03-F25) |

| Application | Ball Valve, Butterfly Valve & Rotary Machines |

Components & Materials of Heavy Duty Scotch Yoke Pneumatic Actuator

Compact Scotch Yoke Pneumatic Actuator Torque Double Acting (N.m.)

Pneumatic Actuator FAQ:

Q1: Pneumatic Valve can’t Move ?

A1: Check the Solenoid Valve is normal or not;

Test the actuator separately with air supply;

Check the handle position.

Q2: Pneumatic Actuator with slow motion ?

A2: Check air supply is enough or not;

Test the Actuator Torque is ok or not for the valve;

Check Valve coil or other components are too tight or not;

Q3: Reply Devices without Signal ?

A3: Inspect and repair power circuit;

Adjust the cam to correct position;

Replace micro switches.