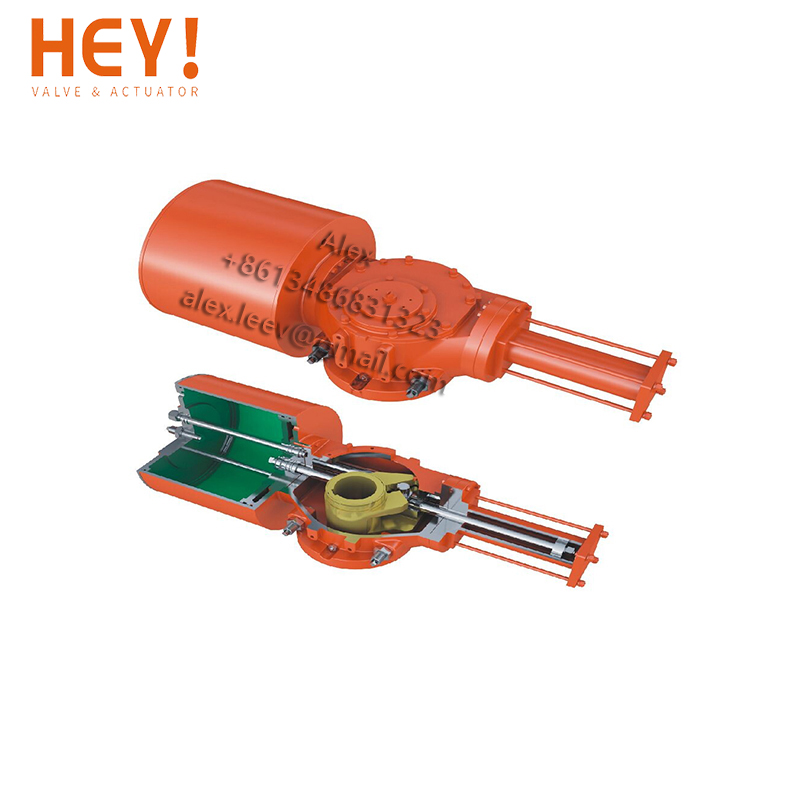

Rack and Pinion Pneumatic Actuator Introduction

The rack and pinion type pneumatic actuator is a versatile device utilized to precisely control valves by utilizing the rotational movement of the gear shaft. This movement is driven by the piston, which engages with the rack and gear through a meshing mechanism.

One of the prominent features of the Rack and Pinion Pneumatic Actuator is its adherence to international standards and its certification with a CE certificate. It complies with recognized industry standards such as NAMUR, ISO5211, and DIN, ensuring compatibility and interoperability with various valve systems. This makes it a reliable and widely adopted choice for valve control applications across different industries.

Furthermore, this actuator boasts an integrated design that emphasizes stability and quality. Its seamless integration ensures stable and reliable performance, even in demanding industrial environments. With a dual piston rack and pinion design, this actuator provides high output power, enabling effective and efficient valve control. The dual piston mechanism enhances the actuator's force-generation capability, ensuring optimal valve operation and response.

To facilitate ease of operation and visual indication of the valve position, the Rack and Pinion Pneumatic Actuator is equipped with a multi-position indicator. This feature allows for on-site visual instruction, enabling operators to quickly and accurately monitor the valve's position and status. This not only simplifies troubleshooting but also enhances overall operational efficiency.

|

Product |

Rack and Pinion Pneumatic Actuator |

|

Structure |

Rack and Pinion Rotary Actuator |

|

Rotary Angle |

0-90 Degree |

|

Air Supply Pressure |

2.5-8 Bar |

|

Actuator Body Material |

Aluminum Alloy |

|

Surface Treatment |

Hard Anode Oxidation |

|

Operating Temperature |

Standard Temperature:-20℃ ~ 80℃ Low Temperature:-15℃ ~ 150℃ High Temperature:-35℃ ~ 80℃ |

|

Connection Standard |

Air interface: NAMUR Mounting Hole: ISO5211 & DIN3337(F03-F25) |

|

Application |

Ball Valve, Butterfly Valve & Rotary Machines |

|

Cover Color |

Blue,Black,Orange,Red & Customized Colors as Customer needs |

Components & Materials of Rack and Pinion Pneumatic Actuator

| Part

Number |

Each

Number |

Part Name | Standard Materials | Selected Materials |

| 01 | 1 | Left Cover | Aluminum

Die Casting |

Stainless Steel |

| 02 | 1 | Right Cover | Aluminum

Die Casting |

Stainless Steel |

| 03 | 1 | Body | Aluminum

extrusion |

Stainless Steel |

| 04 | 2 | Piston | Aluminum

Die Casting |

---- |

| 05 | 1 | Output Shaft | Carbon Steel | Stainless Steel |

| 06 | 1 | Cam adjustment | Stainless Steel | ---- |

| 07 | 2 | O-ring(Cover) | NBR | Fluorine or Silicone Rubber |

| 08 | 2 | O-ring(Piston) | NBR | Fluorine or Silicone Rubber |

| 09 | 1 | O-ring(output shaft bottom) | NBR | Fluorine or Silicone Rubber |

| 10 | 1 | O-ring(output shaft at the top) | NBR | Fluorine or Silicone Rubber |

| 11 | 2 | O-ring(adjusting screw) | NBR | Fluorine or Silicone Rubber |

| 12 | 2 | Plug(Cylinder) | NBR | Fluorine or Silicone Rubber |

| 13 | 2 | Bearing(Piston) | POM | ---- |

| 14 | 1 | Bearing(output shaft at the top) | POM | ---- |

| 15 | 1 | Bearing(output shaft bottom) | POM | ---- |

| 16 | 1 | Guide with Bearing(Piston Back) | POM | ---- |

| 17 | 2 | Thrust bearings(output shaft) | POM | ---- |

| 18 | 2 | Gasket(output shaft) | Stainless Steel | ---- |

| 19 | 1 | Flexible file ring | Stainless Steel | ---- |

| 20 | 8 | Cover bolt | Stainless Steel | ---- |

| 21 | 8 | Cover Gasket | Stainless Steel | ---- |

| 22 | 2 | Gasket | Stainless Steel | ---- |

| 23 | 2 | Nut | Stainless Steel | ---- |

| 24 | 2 | Adjustment bolt | Stainless Steel | ---- |

| 25 | 5-16 | Spring Components | Alloy Spring Steel | ---- |

| 26 | 1 | Position indicator | POM | ---- |

| 27 | 1 | Screw of Indicator | POM | ---- |

|

AT - 160 S - K10 F10/12 P27 - 90 - B - A |

A ---Corrosion Resistance Grade: A, B |

| B ---Ambient Temp.: Standard-B, Low Temp.: D, High Temp.: G | |

| 90 ---Rotation Angle: 00~900, 00~1200, 00~1800, 3 Position, 00~450~900 | |

| P27 ---Shaft Size Code: P-Star Square, H-Parallel Opposite Hole, W Two Key Hole | |

| F10/12 ---Connection: ISO 5211, Flange Size: F03-F25 | |

| K10 ---Spring QTY: K5-K16, Not Available for Double Acting | |

| S ---Type: D-Double Acting, S-Spring Return | |

| 160 ---Cylinder Size:32-400 | |

| AT --- AT Series Pneumatic Actuator |

AT Series Double Acting Rack and Pinion Pneumatic Actuator Torque(N.m.)

| Model\Air Pressure | Air Supply Pressure(Unit: Bar) | ||||||||

| 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | 7 | 8 | |

| AT-40D | 5.7 | 6.7 | 7.6 | 8.6 | 9.5 | 10.5 | 11.4 | 13.3 | 15.2 |

| AT-52D | 12.0 | 14.0 | 16.0 | 18.0 | 20.0 | 22.0 | 24.0 | 28.0 | 32.0 |

| AT-63D | 21.0 | 24.5 | 28.0 | 31.5 | 35.0 | 38.5 | 42.0 | 49.0 | 56.0 |

| AT-75D | 30.0 | 35.0 | 40.0 | 45.0 | 50.0 | 55.0 | 60.0 | 70.0 | 80.0 |

| AT-83D | 45.7 | 53.3 | 61.0 | 68.6 | 76.2 | 83.8 | 91.4 | 106.7 | 121.9 |

| AT-92D | 67.4 | 78.7 | 89.9 | 101.2 | 112.4 | 123.6 | 134.9 | 157.4 | 179.8 |

| AT-105D | 97.6 | 113.9 | 130.2 | 146.4 | 162.7 | 179.0 | 195.2 | 227.8 | 260.3 |

| AT-125D | 152.2 | 177.6 | 203.0 | 228.3 | 253.7 | 279.1 | 304.4 | 355.2 | 405.9 |

| AT-140D | 260.3 | 303.7 | 347.0 | 390.4 | 433.8 | 477.2 | 520.6 | 607.3 | 694.1 |

| AT-160D | 396.6 | 462.7 | 528.8 | 594.9 | 661.0 | 727.1 | 793.2 | 925.4 | 1057.6 |

| AT-190D | 639.3 | 745.9 | 852.4 | 959.0 | 1065.5 | 1172.1 | 1278.6 | 1491.7 | 1704.8 |

| AT-210D | 781.0 | 911.2 | 1041.4 | 1171.5 | 1301.7 | 1431.9 | 1562.0 | 1822.4 | 2082.7 |

| AT-240D | 1147.6 | 1338.8 | 1530.1 | 1721.3 | 1912.6 | 2103.9 | 2295.1 | 2677.6 | 3060.2 |

| AT-270D | 1742.9 | 2033.4 | 2323.8 | 2614.3 | 2904.8 | 3195.3 | 3485.8 | 4066.7 | 4647.7 |

| AT-300D | 2390.8 | 2789.3 | 3187.8 | 3586.2 | 3984.7 | 4383.2 | 4781.6 | 5578.6 | 6375.5 |

| AT-350D | 3580 | 4176 | 4773 | 5369 | 5966 | 6563 | 7159 | 8352 | 9546 |

| AT-400D | 5100 | 5950 | 6800 | 7650 | 8500 | 9350 | 10200 | 11900 | 13600 |

AT Series Spring Return (Single Acting )Rack and Pinion Pneumatic Actuator Torque(N.m.)

| Air Pressure | Spring Torque | spring Torque | |||||||||||||||||||||

| Model | Spring Q.ty | 2.5bar | 3.0bar | 3.5bar | 4.0bar | 4.5bar | 5.0bar | 5.5bar | 6.0bar | 7.0bar | 8.0bar | ||||||||||||

| 00 | 900 | 00 | 900 | 00 | 900 | 00 | 900 | 00 | 900 | 00 | 900 | 00 | 900 | 00 | 900 | 00 | 900 | 00 | 900 | 900 | 00 | ||

| AT-52S | 5 6 7 8 9 10 11 12 |

5.7 5.0 |

3.8 2.6 |

7.7 7.0 6.1 |

5.8 4.6 3.4 |

9.7 9.0 8.1 7.3 |

7.8 6.6 5.4 4.1 |

11.7 11.0 10.1 9.3 8.4 |

9.8 8.6 7.4 6.1 4.9 |

13.7 13.0 12.1 11.3 10.4 9.5 |

11.8 10.6 9.4 8.1 6.9 5.6 |

15.7 15.0 14.1 13.3 12.4 11.5 10.7 |

13.8 12.6 11.4 10.1 8.9 7.6 6.4 |

17 16.1 15.3 14.4 13.5 12.7 11.8 |

14.6 13.4 12.1 10.9 9.6 8.4 7.2 |

18.1 17.3 16.4 15.5 14.7 13.8 |

13.4 12.1 10.9 9.6 8.4 7.2 |

21.3 20.4 19.5 18.7 17.8 |

18.1 16.9 15.6 14.4 13.2 |

24.4 23.5 22.7 21.8 |

20.9 19.6 18.4 17.2 |

6.2 7.4 8.6 9.9 11.1 12.4 13.6 14.8 |

4.3 5 5.9 6.7 7.6 8.5 9.3 10.2 |

| AT-63S | 5 6 7 8 9 10 11 12 |

10.7 9.3 |

7.1 5 |

14.2 12.8 11.4 |

10.6 8.5 6.4 |

17.7 16.3 14.9 13.6 |

14.1 12 9.9 7.8 |

21.2 19.8 18.4 17.1 15.7 |

17.6 15.5 13.4 11.3 9.2 |

24.7 23.3 21.9 20.6 19.2 17.8 |

21.1 19 16.9 14.8 12.7 10.6 |

28.2 26.8 25.4 24.1 22.7 21.3 20 |

24.6 22.5 20.4 18.3 16.2 14.1 12.1 |

30.3 28.9 27.6 26.2 24.8 23.5 22.1 |

26 23.9 21.8 19.7 17.6 15.6 13.5 |

32.4 31.1 29.7 28.3 27 25.6 |

23.9 21.8 19.7 17.6 15.6 13.5 |

38.1 36.7 35.3 34 32.6 |

32.3 30.2 28.1 26.1 24 |

43.7 42.3 41 39.6 |

37.2 35.1 33.1 31 |

10.4 12.5 14.6 16.7 18.8 20.9 22.9 25 |

6.8 8.2 9.6 10.9 12.3 13.7 15 16.4 |

| AT-75S | 5 6 7 8 9 10 11 12 |

14.5 12.3 |

10.5 7.6 |

19.5 17.3 15.2 |

15.5 12.6 9.7 |

24.5 22.3 20.2 18.1 |

20.5 17.6 14.7 11.8 |

29.5 27.3 25.2 23.1 21 |

25.5 22.6 19.7 16.8 13.9 |

34.5 32.3 30.2 28.1 26 23.9 |

30.5 27.6 24.7 21.8 18.9 16 |

39.5 37.3 35.2 33.1 31 28.9 26.8 |

35.5 32.6 29.7 26.8 23.9 21 18.1 |

42.3 40.2 38.1 36 33.9 31.8 29.7 |

37.6 34.7 31.8 28.9 26 23.1 20.3 |

45.2 43.1 41 38.9 36.8 34.7 |

34.7 31.8 28.9 26 23.1 20.3 |

53.1 51 48.9 46.8 44.7 |

46.8 43.9 41 38.1 35.3 |

61 58.9 56.8 54.7 |

53.9 51 48.1 45.3 |

14.5 17.4 20.3 23.2 26.1 29 31.9 34.7 |

10.5 12.7 14.8 16.9 19 21.1 23.2 25.3 |

| AT-83S | 5 6 7 8 9 10 11 12 |

22.2 19 |

15 10.4 |

29.9 26.7 23.6 |

22.7 18.1 13.5 |

37.5 34.3 31.2 28 |

30.3 25.7 21.1 16.5 |

45.2 42 38.9 35.7 32.5 |

38 33.4 28.8 24.2 19.6 |

52.8 49.6 46.5 43.3 40.1 37 |

45.6 41 36.4 31.8 27.2 22.6 |

60.4 57.2 54.1 50.9 47.7 44.6 41.4 |

53.2 48.6 44 39.4 34.8 30.2 25.6 |

64.8 61.7 58.5 55.3 52.2 49 45.8 |

56.2 51.6 47 42.4 37.8 33.2 28.6 |

69.3 66.1 62.9 59.8 56.6 53.4 |

51.6 47 42.4 37.8 33.2 28.6 |

81.4 78.2 75.1 71.9 68.7 |

69.9 65.3 60.7 56.1 51.5 |

93.4 90.4 87.1 83.9 |

80.5 75.9 71.3 66.7 |

23 27.6 32.2 36.8 41.4 46 50.6 55.2 |

15.8 19 22.1 25.3 28.5 31.6 34.8 38 |

|

AT-92S |

5 |

32.8 |

21.7 |

44.1 |

33 |

55.4 |

44.3 |

66.6 |

55.5 |

77.9 |

66.8 |

89.1 |

78 |

95.6 |

82.4 |

102.2 |

75.5 |

120.1 115.4 110.7 106 101.4 |

102.4 95.5 88.7 81.8 74.9 |

137.8 133.1 128.4 123.8 |

117.9 111.1 104.2 97.3 |

34.4 |

23.3 |

|

AT-105S |

5 |

49.7 |

32.1 |

66 |

48.4 |

82.3 |

64.7 |

98.6 |

81 |

114.8 |

97.2 |

131.1 |

113.5 |

141 |

119.9 |

150.9 |

110.1 |

177.2 170.9 164.5 158.2 151.9 |

149.1 139.2 129.4 119.8 109.8 |

203.4 197 190.7 184.4 |

171.7 161.9 152.3 142.3 |

49.2 |

31.6 |

|

AT-125S |

5 |

74.8 |

47.8 |

100.2 |

73.2 |

125.6 |

98.6 |

151 |

124 |

176.3 |

149.3 |

201.7 |

174.7 |

216.1 |

185.1 |

231.4 |

169.1 |

271.2 261.2 250.2 240.2 230.2 |

230.2 214.2 198.2 182.2 167.2 |

311.9 300.9 290.9 280.9 |

264.9 248.9 232.9 217.9 |

79 |

52 |

|

AT-140S |

5 |

130.9 |

87.9 |

174.3 |

131.3 |

217.7 |

174.7 |

261 |

218 |

304.4 |

261.4 |

347.8 |

304.8 |

374.2 |

322.2 |

400.6 |

296.2 |

470.3 452.3 435.3 418.3 401.3 |

401.3 375.3 349.3 323.3 297.3 |

539.1 522.1 505.1 488.1 |

462.1 436.1 410.1 384.1 |

129 |

86 |

|

AT-160S |

5 |

190.5 |

122.5 |

256.6 |

188.6 |

322.7 |

254.7 |

388.8 |

320.8 |

454.9 |

386.9 |

521 |

453 |

559.1 |

477.1 |

597.2 |

435.1 |

702.4 674.4 646.4 618.4 590.4 |

592.4 550.4 508.4 467.4 425.4 |

806.6 778.6 750.6 722.6 |

682.6 640.6 599.6 557.6 |

208 |

140 |

|

AT-190S |

5 |

333 |

224 |

440 |

331 |

546 |

437 |

653 |

544 |

759 |

650 |

866 |

757 |

933 |

802 |

999 |

740 |

1172 1132 1092 1052 1012 |

997 935 874 812 750 |

1346 1306 1266 1226 |

1149 1088 1026 964 |

309 |

200 |

|

AT-210S |

5 |

376 |

271 |

506 |

401 |

636 |

531 |

767 |

662 |

897 |

792 |

1027 |

922 |

1102 |

976 |

1177 |

900 |

1383 1328 1273 1218 1163 |

1215 1139 1063 987 911 |

1588 1533 1478 1423 |

1399 1323 1247 1171 |

380 |

275 |

|

AT-240S |

5 |

547 |

403 |

738 |

594 |

929 |

785 |

1120 |

976 |

1312 |

1168 |

1503 |

1359 |

1612 |

1439 |

1721 |

1329 |

2022 1939 1857 1775 1693 |

1792 1680 1570 1459 1348 |

2322 2240 2158 2076 |

2063 1953 1842 1731 |

554 |

410 |

|

AT-270S |

5 |

892 |

665 |

1183 |

956 |

1473 |

1246 |

1764 |

1537 |

2054 |

1827 |

2345 |

2118 |

2523 |

2252 |

2703 |

2094 |

3172 3060 2948 2836 2725 |

2809 2651 2495 2337 2180 |

3641 3529 3417 3306 |

3232 3076 2918 2761 |

787 |

560 |

|

AT-300S |

5 |

1263 |

932 |

1661 |

1330 |

2060 |

1729 |

2458 |

2127 |

2857 |

2526 |

3255 |

2924 |

3508 |

3111 |

3760 |

2899 |

4411 4265 4119 3973 3827 |

3882 3670 3457 3245 3033 |

5062 4916 4770 4624 |

4467 4254 4042 3830 |

1061 |

730 |

Pneumatic Actuator FAQ:

Q1: Pneumatic Valve can’t Move ?

A1: Check the Solenoid Valve is normal or not;

Test the actuator separately with air supply;

Check the handle position.

Q2: Pneumatic Actuator with slow motion ?

A2: Check air supply is enough or not;

Test the Actuator Torque is ok or not for the valve;

Check Valve coil or other components are too tight or not;

Q3: Reply Devices without Signal ?

A3: Inspect and repair power circuit;

Adjust the cam to correct position;

Replace micro switches.